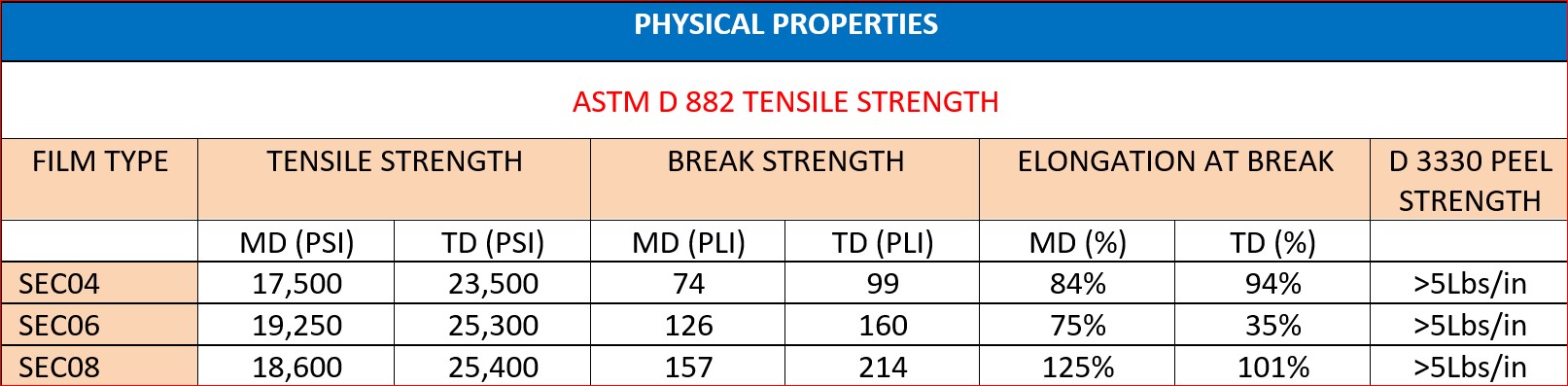

TENSILE STRENGTH (PSI) The tensile strength of a material is the maximum amount of stress that it can take before failure, such as breaking or permanent deformation. It is calculated by dividing the maximum load by the original minimum cross sectional area of the specimen. Calculated up from break strength.

BREAK STRENGTH (LBS/IN WIDTH) Breaking strength is that force which is required to break the specimen. The appropriate reporting unit for this test is pounds per lineal inch. Used to determine tensile strength.

ELONGATION AT BREAK Presented as a percentage in relation to the initial length before elongation. It is calculated by dividing the extension at the moment of rupture in the specimen multiplied by 100. It represents the amount of stretch exhibited by the sample prior to the failure point.

PEEL STRENGTH The force required to remove coated material from a prescribed surface measured in pounds per inch

Just see these videos to see how safety films work: